If it comes to efficient, reliable, and cost-effective rail systems the Powerline PLUS Train Backbone (PTB) stands out as the future of freight train communication. PTB is a cutting-edge Power Line Communication (PLC) solution designed to streamline data transmission across freight trains by utilizing the train power distribution line.

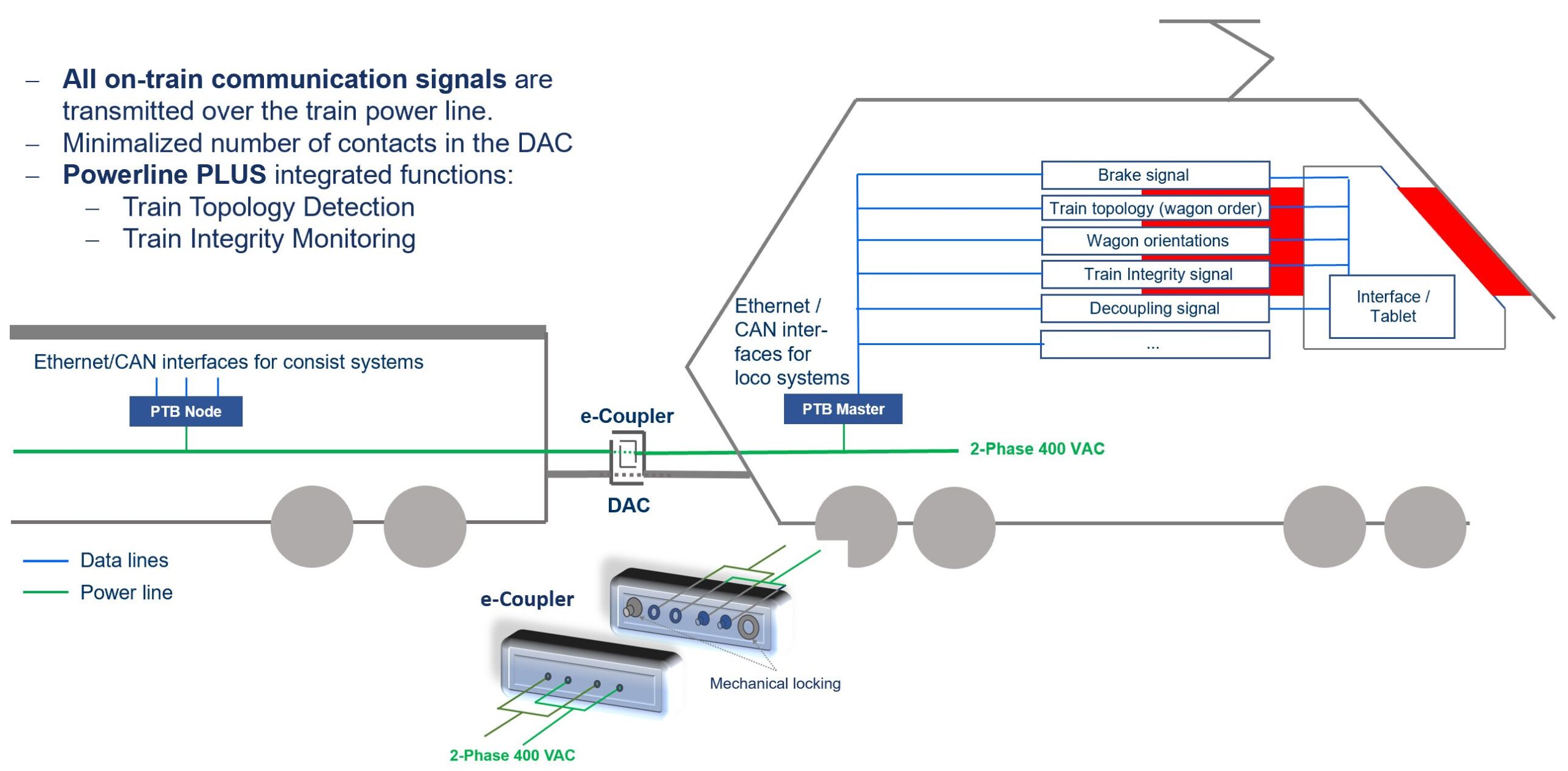

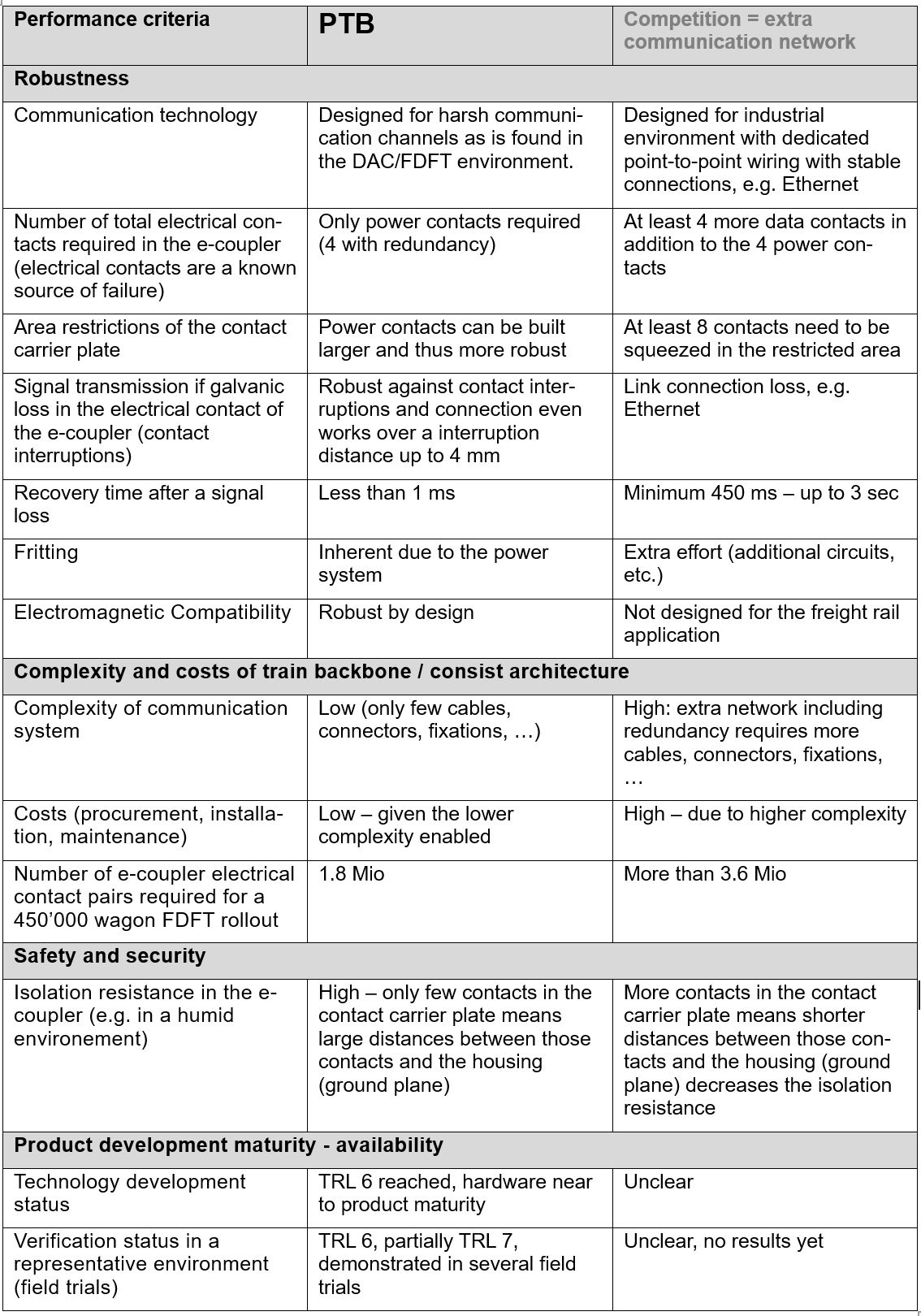

No Extra Communication Network Needed: Unlike competing technologies, PTB transmits data over the train’s power distribution line, eliminating the need for a separate communication network. This innovative approach means no additional data contacts are required in the digital automatic couplers between wagons, leading to a simpler, more reliable and cost-effective system.

Higher Reliability and Lower Complexity: PTB is based on the PLUS (Power Line data bUS) technology, a technology specifically targeting reliable PLC. By reducing the number of components and connections, PTB increases system reliability while lowering both complexity and costs. This translates into more efficient operations, less maintenance, and greater overall system uptime.

Field-Proven and Future Oriented Technology: PTB is not just a concept – it’s a proven solution. We’ve successfully demonstrated PTB in the field, setting us apart from competitors who are still in the theoretical or testing phases. Its forward-looking design ensures long-term availability and adaptability to future needs.

Complete Product Design: PTB is available as a fully developed electronic product, including hardware/PCB schematics and VHDL firmware. This ready-to-integrate design allows system suppliers and rail electronics providers to quickly incorporate PTB into their offerings, reducing development time and costs.

Seamless Integration: Whether you are developing train data networks, power systems, or other rail electronics, PTB offers a flexible and powerful backbone that enhances the performance and reliability of your products.

Market-Ready and Proven: PTB has already demonstrated its effectiveness in real-world operational conditions, making it a market-ready solution with immediate value. This positions us ahead of competitors and presents a strong opportunity for technology partnerships.

Attractive IP Licensing Model: Our IP licensing model offers a flexible approach for partners to integrate PTB into their own products, allowing them to stay competitive while minimizing costs and accelerating time to market.

As the rail industry moves towards more integrated and reliable systems, PTB is the backbone technology designed to drive this transformation. Whether you are a system supplier, rail electronics provider, etc. looking for a strategic technology partnership, PTB offers a unique combination of proven / reliable performance, lower complexity / simplicity, and cost savings.

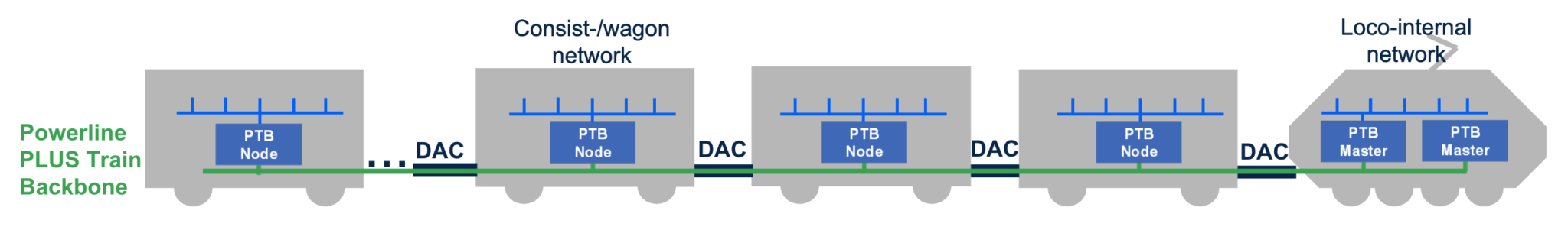

PTB has been designed as a train backbone network where the data is transmitted via the train’s distribution power line. This has the advantage that the train backbone network requires

Compared to competing solutions with an extra data communication network this means

PTB has been designed to transmit ALL signals of the automated and digitalized train functions of the Full Digital Freight Train (FDFT), including control and monitoring signals of the Train Composition Detection, Automatic Brake Test, Train Integrity Monitoring, Remote Uncoupling of wagons, Passive-Consist Detection and Train Wakeup, Multi-traction, monitoring ot the train energy system, etc.

To meet the requirements of such train functions, PTB benefits from the USPs of the underlying PLUS physical layer which was developed a priori for extremely difficult communication channels and uses state-of-the-art techniques to ensure robust communication:

Based on this physical layer new higher protocol optimized for freight train automation functions were developed

In contrast to competing technologies for the train backbone PTB profits from having been designed a priori for the most difficult communication channels and is therefore optimally adapted for the harsh conditions on a freight train.

Full Digital Freight Train (FDFT) systems must function robustly and reliably in all tough conditions in the operational processes. Laboratory tests are not sufficient to make a reliable statement regarding robustness. plc-tec with its partner SBB Cargo and supported by the Swiss Federal Office of Transport has therefore pushed for tests and trials of PTB prototypes in the field right from the start and integrated the results into their further developments. PTB has been tested in the following projects:

DAC4EU (from 2021 till today)

In the DAC4EU project PTB is tested as one of the communication technology candidates for the FDFT train backbone. PTB modem prototypes have been integrated into all wagons of the DAC4EU train.

Results published at the end of 2022 (link to the detailed results below) confirmed that PTB had achieved the best results of the three tested technologies and, e.g. reliably recorded train integrity and wagon order.

Swiss DAC+ Test Train (from 2022 till today)

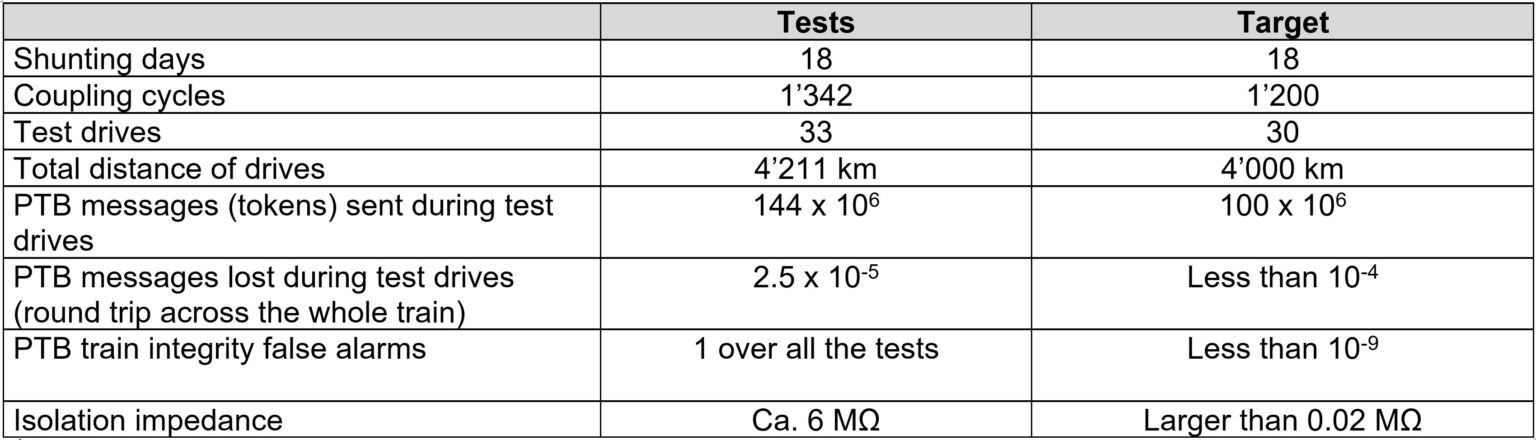

A consortium led by SBB Cargo tested PTB as train backbone communication system for the automated train functions Train Composition Detection, Automatic Brake Test, Train Integrity Monitoring, Uncoupling from the locomotive, etc. with the required systems (mechanical, power and communication). Component prototypes from plc-tec, Voith and PJ Messtechnik were integrated on the DAC+ Test Train. The focus was on testing the reliability of the automated train functions and the required systems supporting them under harsh environmental conditions. For that goal various measurement equipment was installed on the train. Extensive standing, shunting and drive tests throughout Switzerland incl. the Gotthard and Lötschberg mountain routes were performed.

Summary of the results of the Swiss DAC+ Tests

The tests for the PTB communication system showed very high performance in terms of the important variables of message error rate (in the range of 10^-5), very low false alarm rate for train integrity, and latency (in the low single-digit ms range) as a basis for reliably meeting the communication requirements of the train functions.

Europe’s Rail Joint Undertaking (ERJU)

Flagship Project 5: TRANS4M-R – Transforming Europe’s Rail Freight (2022 till today)

FP5-TRANS4M-R brings together 71 partners from across the rail sector including end-users, industrial partners, railway undertakings, operators, wagon keepers, SMEs and academia.

plc-tec contributes to the WP18 SBB DEMO: DAC Powerline PLUS Communication Solution. plc-tec’s work is focused on new train functions Passive Consist Detection and Train Wake-up based on PTB which are tested in the field on the DAC+ Test Train.

Comparison to competing solutions

PTB Application Note No. 1 – DAC+ TEST SYSTEM FOR AUTOMATED TRAIN FUNCTIONS

PTB Application Note No. 2 – TEST RESULTS OF THE AUTOMATED TRAIN FUNCTIONS TRAIN COMPOSITION DETECTION AND TRAIN INTEGRITY MONITORING

PTB Application Note No. 3 – FINAL TEST RESULTS OF THE MAJOR AUTOMATED TRAIN FUNCTIONS

Wakeup & Passive Consist Detection Proven in DAC+ Field Tests (October 2025)

Virtual Train Lab at Lucerne University of Applied Sciences and Arts (HSLU) (February 2024)

DAC+ Final test results of the major Train Functions (September 2024)

The DAC+ Train – Test results of the Automated Train Functions (August 2023)

The DAC+ Train – Test System (July 2023)

DAC+ tests have started in Switzerland (March 2023).

Hightech Zentrum Aargau (HTZ) 10th anniversary event (August 2023)

PLC Train Backbone (PTB) Demo with VOITH and HVLE (October 2021)

Hightech Zentrum Aargau (HTZ) 10th anniversary event including the full presentation of Prof. Dr. Jürgen Wassner, CDO of plc-tec. (August 2023)

Swiss TV report about future digital freight train

2025 plc-tec.ch – plc-tec AG | ALL RIGHTS RESERVED – IMPRESSUM | UMSETZUNG WEBTOTAL.INFO